AGV & AMR

automation solutions

for any industry and environment

- Navigation & Localization

- Fleet Control

- Simulation

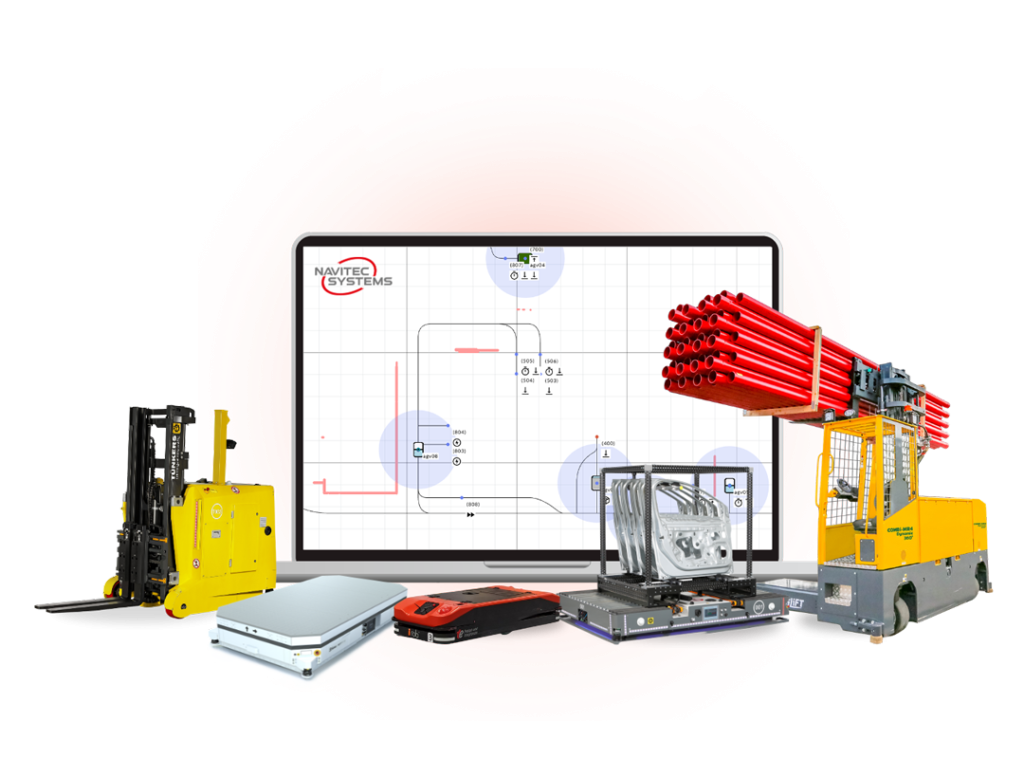

With Navitec’s modular software stack and hardware-independent architecture, customers can quickly develop new AGV and AMR types & competitive automation solutions with Universal Fleet Control and WMS/WCS option.

Drive autonomously

anywhere you want

Any industry

Drive with AGVs and AMRs in any material handling environment

Any complexity

Reach smooth traffic even in high density and complex route structures

Indoor and outdoor

Automated material handling regardless of environment

Automate all production stages:

from production line to warehouse, seamlessly

Our complete software solution enables automating every stage of the material flow process – from your shop floor to the warehouse, all within a single, integrated system. Our automation allows for effortless transition of your autonomous fleet from indoor to outdoor environments, despite the location complexity and weather conditions.

Navitec can automate any type of vehicle, independent of size, type of drive system (electric or hydraulic), number of drive axes, and the environment – indoor and outdoor in any weather. Our AGV navigation system and fleet management software are designed for both AGVs and AMRs.

We offer free assistance for vehicle design and guarantee the shortest integration time at a fixed price.

Any AGV & AMR

Indoors & outdoors

Fast deployment

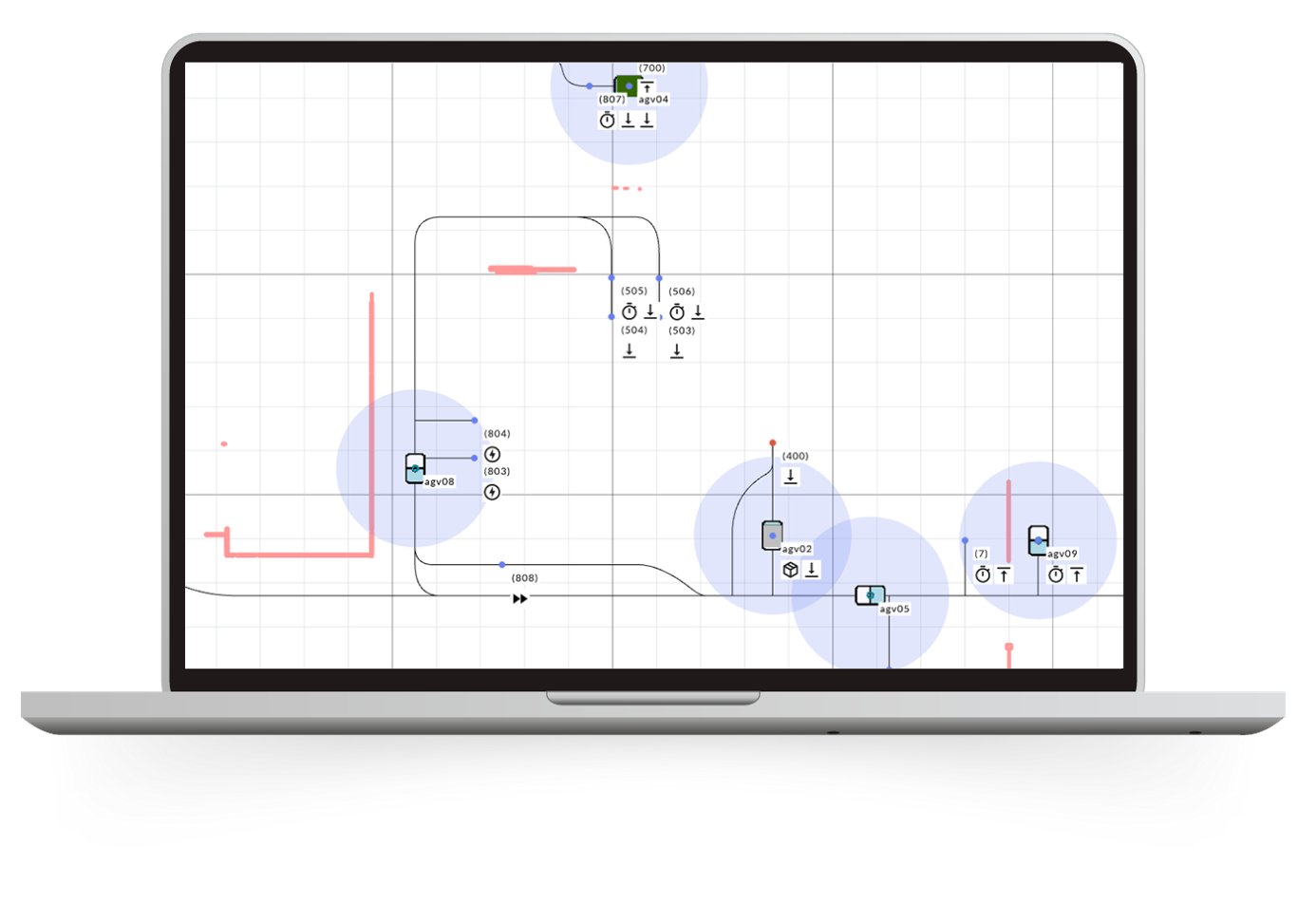

Our Advanced Fleet Management System seamlessly integrates with factory environment and provides stable traffic in any density.

- High traffic density

- Superior control algorithms

- Continuous efficient production flow

- Complex route systems

- Communication with hand-held devices, PLSs and WMS/WCS/MES

- Fully integrated with factory environment

- Supported diverse fleets (VDA5050)

- With the simulation tool, efficient planning of new systems can easily be achieved

VDA5050 supported

Easily scalable

High density traffic

Integration with factory systems allows for coordinating your entire material flow, from production to warehouse. The integration of AGVs and AMRs with your factory systems offers a lot of advantages, including enhanced efficiency of your workflow, optimized resource management, reduced downtime, cost savings and easy scalability.

Seamless integration

WMS, WCS, ERP, MES

Real-time tracking

Types of factory systems:

WMS

WMS – Warehouse Management System

A software solution designed to manage and optimize warehouse operations. The main functionality includes inventory and order management.

WCS

WCS – Warehouse Control System

This is a software solution for logistics and warehouse management to optimize and control the physical aspects of warehouse operations – conveyor belts, sorters. While Warehouse Management System (WMS) primarily focuses on managing inventory and order processing, a WCS is focused on automating and orchestrating the flow of inventory within a warehouse. Typical functionality of WCS involves real-time control of material handling, task assignment, storage optimization, equipment and machinery coordination, and more.

ERP

ERP – Enterprise Resource Planning

A comprehensive software system to manage and streamline the core processes and functions across various departments and operations. ERP software integrates data and processes from different areas of a business into a unified and centralized system.

MES

MES – Manufacturing Execution System

A comprehensive software system for managing, monitoring, documenting, and controlling various aspects of manufacturing operations on the shop floor, from raw materials to finished products. It acts as a bridge between the ERP (Enterprise Resource Planning) system and the automation systems on a production site. The system provides real-time production control, production data collection, work order management, inventory management, reporting and analytics, equipment maintenance and more.

We are also offering smooth integration with factory systems with our partner Roima – a solution platform provider specializing in intra and outdoor logistics, including WMS, WCS, ERP, and MES. Roima offers a modular cloud-based real-time software solution that integrates seamlessly with Navitec Fleet Control. Roima has over 30 years of experience in intralogistics and is a specialist in continuous improvement of supply chain efficiency.